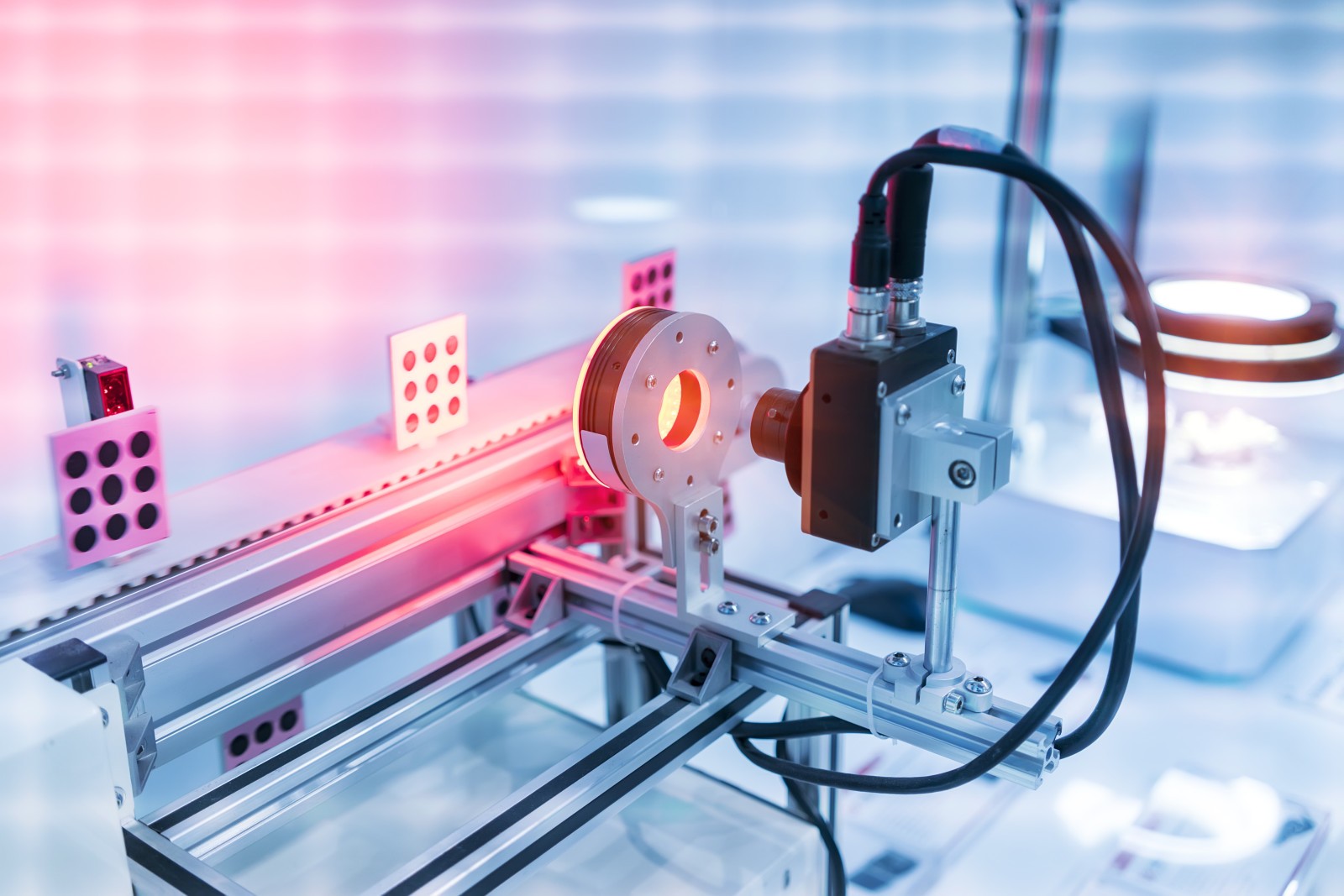

uSpot

The Artificial Intelligence and Machine Vision tool for production control

▪ Visual inspection: Dynamically analyze products on the production line to perform quality checks and more accurately identify defective components.

▪ Sorting: Enables all types of sorting tasks to be conducted throughout the entire manufacturing process.

▪ Maintenance: Perform automatic analysis of the status of all types of mechanisms and systems used in production processes (cranes, tracks, belts, etc.) to detect possible failures or even, predictively, to anticipate them.

▪ Scalable: possibility of implementation in other customer lines and compatible with the cloud.

▪ Flexible: ability to adapt to different industrial processes.

▪ Modular: enables multiple functionalities to be leveraged.

▪ Image processing in real time.

▪ Neural networks with pre-trained architectures that can be adapted to all use cases.

▪ In addition to the image, it incorporates context information (line speed, ambient temperature, time since last defect, etc.) to increase the accuracy and stability of the entire process.

▪ Use of leading open-source imaging and data processing technologies for optimal performance.

▪ It enables the project to evolve in the direction required by the customer without technological limitations.

Advanced Factories

Details

9:30 AM - 6:30 PM

Wine Innovation Week