Industry 4.0 harnesses Big Data to forge customer loyalty

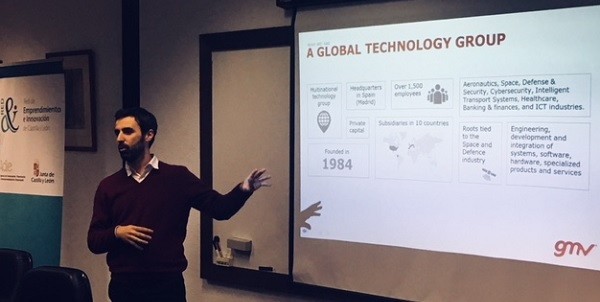

The Technology Center Foundation of Miranda de Ebro (Fundación Centro Tecnológico de Miranda de Ebro: CTME), with the collaboration of the Business Competitiveness Institute of Castilla y León (Instituto para la Competitividad Empresarial de la Junta de Castilla y León) has brought together in Burgos specialists from universities and companies in the event: “Turn your company’s data to good account”. Pablo González, GMV Data Scientist, gave a paper sharing his experiences of working with data-related projects, demystifying the basic concepts of projects of this type and helping to bring them down to earth.

In González’s words “Spanish industry, following in the wake of other European countries, is now jumping on the Big Data wagon in the interests of boosting quality, productivity and after-sales service with its clients”. “We can’t afford to stand on the wayside of the fourth industrial revolution and fall behind the market”. GMV’s expert also stressed the most important aspect in ensuring the success of a Data Science project, namely: “making sure the use case and the need to be met is well defined beforehand, tackling small, rapid-innovation projects adding great value at minimum risk”.

González pointed out that Forbes Technology, in a 2015 report, has already revealed that Rolls-Royce Motors applies a Big Data strategy in its two new UK factories to guarantee the highest quality standards of its aircraft and ship engines. The company monitors and studies continuously the terabytes and petabytes provided by its sensors in the manufacturing process.

Likewise, he also highlighted the fact that, although advanced analytics to extract information from great volumes of data is already with us, “there is still a dearth of professionals to harness the data being stored by companies”.

Another noteworthy feature of the British multinational is that its data scientists working in operational services centers distributed throughout the world analyze all data generated during the use of aircraft and ship engines. Big Data and Analytics thus help Rolls-Royce to decide even weeks beforehand when engine maintenance processes have to be carried out. Communication with its clients is direct, telling them when this maintenance needs to be arranged. This allows airlines to plan aircraft shutdowns and avoid flight cancellation costs. The business is not just selling the engine but also the aftersales maintenance service.